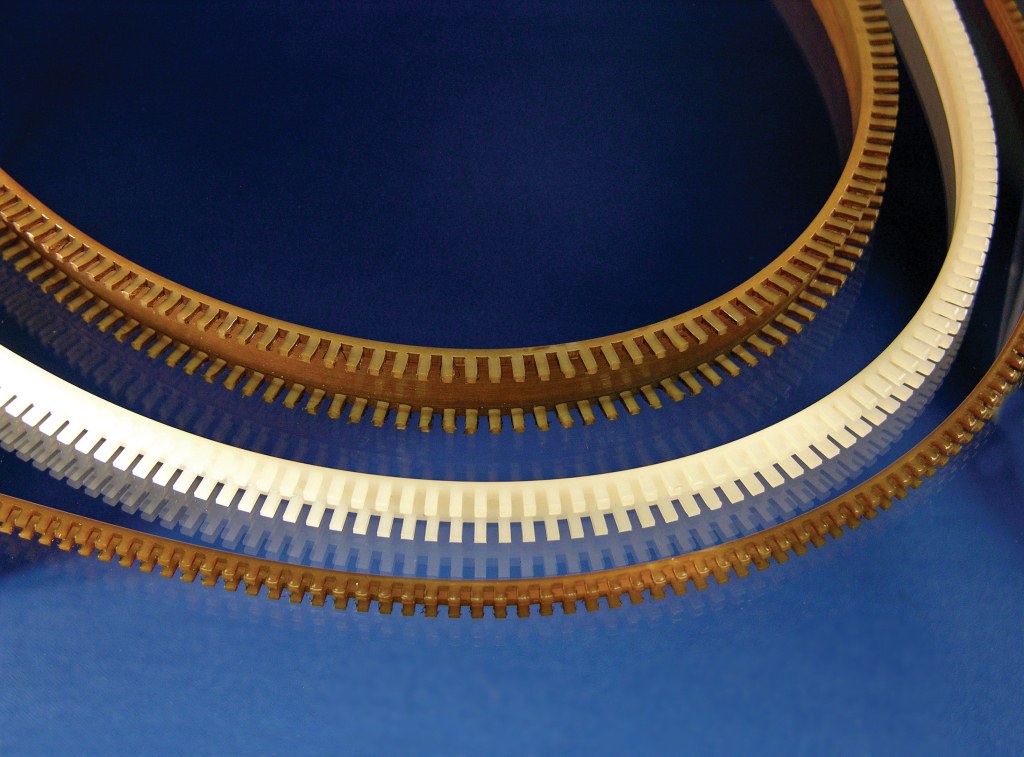

Caterpillar Style Grommets

The Caterpillar Grommet is an ideal solution for a variety of design and production problems. For use in Aircraft, Marine, Electronic, Automotive and Other Applications. Continuous coil lengths can be easily shaped to line and grip holes of various sizes and thicknesses with a single piece. The benefits include the protection of cables and tubing from damage caused by sharp edged holes, eliminating costly errors caused by oversized or undersized holes. It offers excellent insulation and a reduction of scrap material.

The Caterpillar Grommet from NMC is available in Nylon 6 and Polytetrafluoroethylene (PTFE) materials in continuous coil lengths. These products can meet your special needs from extra flexibility to high heat resistance. The Caterpillar Grommet from NMC meets most existing dimensions of current blueprints in the marketplace.

Conforms to MS21266 and BACG20Z specifications except for length.

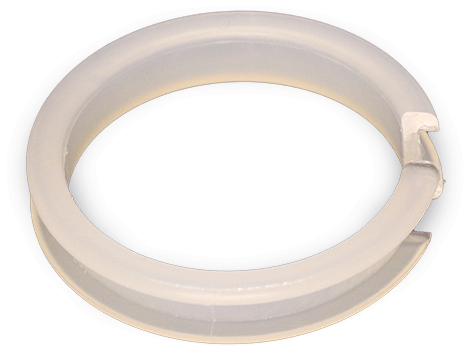

NMC Split Grommet for Round Holes

Split grommets are precision manufactured to be inserted into round holes easily and quickly. Are available for hole sizes of .375″ to 3″ diameter and to fit firmly in normal bulkhead material thicknesses of .025 – .125. Benefits include excellent insulation as well as scuff protection on smooth inner surfaces for wire bundles, cable or tubing. They protect cables from damage by sharp-edged holes, thus eliminating costly repairs.

NMC Split Grommets are available in plastic or PTFE (polytetrafluorethylene) PTFE grommets are chemically etched so that the adhesive will adhere upon assembly. PTFE material is used because of its higher temperature resistance (to 500’F).

Conforms to NAS557 Series

NMC Flip Grommet

NMC manufactures “flip” grommets to the NAS 1368 standard, for use in a variety of applications in the aerospace, industrial, and automotive industries. They are used to protect wire, cable, and tubing passing through holes in bulkheads, frames and other structures. These grommets provide economical chafe protection with low labor costs and can also be used as a bushing or bearing in low PV applications.

A flip grommet is inserted into a hole, then a forming die is placed on each side of the structure. The die sections are drawn together, forming a flange on the open side to a point where the skirt of the grommet “flips” over itself, creating a flange on both sides of the structure.

The die sections can be attached to a toggle type clamp, a pneumatic tool, or simple bolt and nut through the center. Many companies have developed unique tools to speed application or access difficult areas.

The key to successful application of the flip grommet is to select the correct grommet size for the application and the structure thickness.

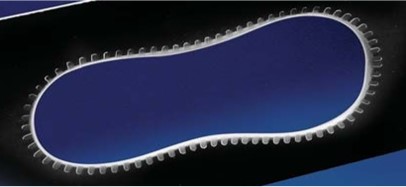

Flanged Hole Grommet

Flanged hole grommets are an ideal solution for a variety of design and production problems. For use in Aircraft, Marine, Electronic, Automotive and other applications. They enable grommets to be use in irregular, odd shaped or large holes, easily and quickly. They readily shape to line almost any shaped opening, offering excellent insulation. They also act as a chafe guard, protecting wire bundles, cable and tubing from sharp or jagged edges.

Flanged hole grommets are available in Nylon 6 and Nylon 6/6 materials for flexibility and durability. The standard stock length is 19.00″ which can fit holes up to 6″ in diameter. Flanged hole grommets from NMC meet existing dimensions of current industry blueprints.