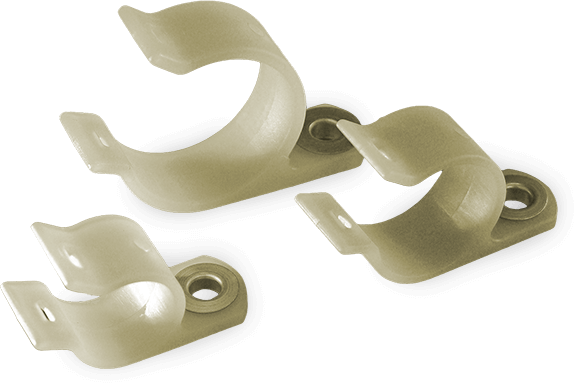

Wire Management Clamps with Eyelet Feature

The support clamp with eyelet is designed for heavy-duty wire management needs. The metal eyelet, added to the mounting hole, distributes the load, relieves stress concentration and gives added strength and protection. It is ideal for holding wires, and wire harnesses. Support clamps provide excellent stability under vibration as well as continuous circular support.

It meets all existing dimensions of current blueprints in the marketplace and it conforms to MS25281-R dimensions. The support clamp with eyelet is available in sizes from.125″ to 2.00″ diameter.

Pre-mountable Clamps for Varied Wire Bundle Installations

Pre-mounted adjustable design is excellent for installing wire bundles and hydraulic lines. Varying sizes of wire bundles can be securely clamped with plastic cable ties (MS3367), used in conjunction with the adjustable clamp. No need to remove clamp. Cut and discard cable ties for easy servicing of wire bundles and hydraulic lines. Cables and hydraulic lines can be re-secured with a new tie down strap. Available with metal eyelet securely crimped to the mounting hole to help distributes the load and relieves stress concentration. Can be immersed in aircraft fuel. Material 6/6 nylon, heat stabilized.

Adjustable clamps 90 degree are available for cable bundle diameters from 1/8″ to 2-3/16″. They open at a 90-degree angle for easy installation of wires. The part number will be NMC 1005-X.

Adjustable clamps 30 degree are available for diameters from .250″ to 1.250″. Five nominal sizes are available. Clamp opens at a 30-degree angle can be used in stacked installations

Support Clamp for Multiple Type Applications with Eyelet Feature

This support clamp with eyelet is designed for heavy-duty use. The metal eyelet added to the mounting hole distributes the load and relieves stress concentration. Excellent for wire bundles and hydraulic lines. Light weight design includes exclusive wiping action to prevent pinching. Nylon is impervious to Skydrol, other fuels and chemicals. Flexible nylon permits variety of mounting methods such as in-line, flush base or butterfly. One-piece design gives maximum cushioning and eliminates abrasion.

The Support Clamp (-F) meets all existing dimensions of current blueprints in the marketplace and it qualifies to MS 25281-F dimensions. It is available in sizes from .125″ to 1.25″ in diameter.

Nylon Molding Corporation (NMC) Color Coded Clamps. Save time and reduce errors in installation and inspection by only having to glance at the final assembly for correct sizing. Available in nineteen different sizes of clamps and come in a series of seven colors. Sizes from.125″ to 1.5″.

Each clamp is designed for the aircraft industry and meets all the quality and structural requirements for plastic clamps.

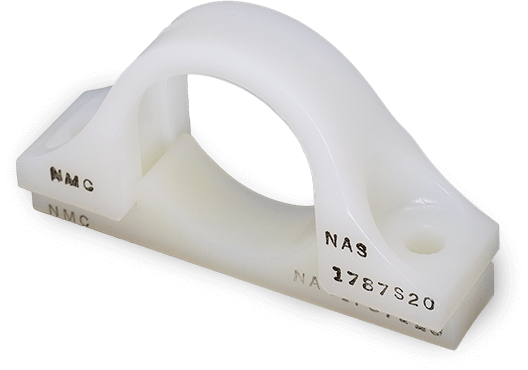

Tube Support Clamps

Tube support clamps for Aircraft, Marine, Electronic, Automotive, etc. Uses include supporting fuel lines, environmental control lines, hydraulic lines and other miscellaneous air and fluid lines. They are made of lightweight nylon and offer exceptional toughness and tensile strength. Among their advantages are that they provide a cushioning effect, withstand constant vibration and shock loads, are noncorrosive, weather-proof, fungus-proof, lightweight, strong and durable. Tube support clamps are available with aluminum ground strip bonded to the base. They are made of 6/6 nylon that is self-extinguishing and heat stabilized when tested in accordance with ASTM D4066. These clamps can be immersed in aircraft fuel.

NMC S770100 Series conforming to NAS1787 Series. They come in sizes that grip tubes from 1″ to 9″ in size.

NMC CA7500 Series is Available in 23 sizes, from 1.0″ to 6″.

Raceway Channel Clamps

Raceway wire channel clamps offer wire management flexibility for ease of clamp installation and removal. They feature a lightweight, rugged design that has good chemical and heat resistance as well as strength and durability. Raceway clamps are available in two lengths – 2.62″ and 4.00″ – and can be configured to various heights. These wire bundle channels are used extensively in commercial aircraft design for multiple applications of wire design and tube support. Additional clips can be added to ensure wire separation when necessary.

Both designs of the Raceway Channel are made from nylon 6/6 materials which offer maximum flexibility and durability. The material conforms to industry specification ASTM D4066. The bracket material is a combination of aluminum and foam, offering firm support for wiring and tubing. The foam has low to no smoke and toxicity features.